Basics

- Project TitleIntroduction to Die Cutting

- Employer SiteCentury Box

- Submitted By (Teacher Name)Daniel Burns

- SchoolGreater Lawrence Technical School

- Brief Description and Rationale Today`s Graphic Communication shop needs to address Package Printing. Packaging is a $400 billion dollar a year industry. We have many packaging companies in our community.

Die Cutting is the process in which a flat printed sheet of paper is cut into the shape of a folding carton. Century Box, in Methuen Ma, produces millions of these each month. The cut, flat, boxes are folded and glued together and ultimately shipped to product manufacturers to package their products. In this unit, students will be exposed to the basics of die cutting. Students will perform Layout and Nesting using Cimex software.

- Grade Level11

- Materials / ResourcesSee attached.

-

View/Download File: /project766_3815/Die_Cutting_Materials.pdf

- Duration of lessonFive Days

Day one: 45 min

Day two: 45 min

Day three: 45 min

Day 4: 45 minutes

Day 5: 45 minutes

- Key Vocabulary / Word WallSee attached material sheet.

-

View/Download File: /project766_3815/Die_Cutting_Word_Wall.pdf

- Pre-Requisite Knowledge2.C.02.01 Define units of measurement and proper uses of each.

2.I.01.08 Cut materials to given specifications, utilizing stock cutting math formula - Strategies to promote equityBy Communicating Classroom Standards, active listening, and trying to identify moments of bias.

- Instructional ObjectivesEssential Question:

Why is die cutting important?

How can we determine quality of a product?

SWBAT:

Identify the important elements of a quality die cut blank.

Identify the components of a die board.

Use Cimpack software to layout out a die board.

Identify if a product meets a specification.

Lesson #1 | What is die cutting?

- Lesson Plan 1 TopicWhat is die cutting?

- Lesson plan 1 objectivesTo understand the process of converting a flat sheet of paper into packaging.

- Anticipatory set or lesson opening (to activate students` prior learning or draw student interest or involvement)Open up with samples of the bookmark project. It was printed on the offset press and then cut on the paper cut. A very basic project. We‘ve seen printed cartons, how do they go from being a flat sheet of paper to a shape that can protect and show off a product?

- Direct InstructionAfter class discussion on what we think die cutting is and how it is done the students will watch the video from Packfactory.

In pairs, students will use 2-column notes to journal positive & negative findings. -

View/Download File: /project766_3815/basic_die_cutting.mp4

View/Download File: /project766_3815/Lesson_One_Two_Column_Note.pdf

- Guided PracticeStudents will be handed cut/scored sample cartons. We will examine the cuts/creases/perforations. We will then fold the boxes up along their creases.

- Independent Practice/Differentiated ActivitiesStudents will then use the scoring boards to attempt to manually create similar creasing. It‘s much harder than you would think.

- Reflection on Employability SkillsA class discussion on the critical part die cutting plays in $400 billion dollar a year packaging industry.

- Lesson ClosureThere will be an exit ticket that will have the students right out two things they liked and one thing they don‘t understand.

-

View/Download File: /project766_3815/Die_Cutting_Exit_Ticket.pdf

- Summative/end of lesson assessmentStudents will report out to class their two column notes for discussion.

-

View/Download File: /project766_3815/Lesson_One_Two_Column_Note.pdf

- References / Resources / Teacher PreparationAttachment: /project766_3815/basic_die_cutting.mp4

Attachment: /project766_3815/Lesson_One_Two_Column_Note.pdf

Attachment: /project766_3815/Die_Cutting_Exit_Ticket.pdf

Sample Cartons

Scoring Board

Lesson #2 | What makes up a cutting die?

- Lesson Plan 2 TopicWhat makes up a cutting die?

- Lesson Plan 2 ObjectivesStudents should be able to identify various components of a cutting die and rule.

- Anticipatory set or lesson opening (to activate students` prior learning or draw student interest or involvement)A call back discussion to the previous day about what die cutting is. Continuing that conversation to you can`t have die cutting without a cutting die.

- Direct InstructionWe will skim through the video stopping at various sections so that the students can see the lines being burnt into the cutting board with the laser as well as the cutting rule being shaped with an autobender. After the discussion that follows the video I will bring out the cutting dies I have in house. Students will identify the various parts. I will review the different types of cutting rule on the dies and show them samples with them demonstrated.

-

View/Download File: /project766_3815/cutting_die_and_rule.mp4

View/Download File: /project766_3815/Die_Board_Graphic_Organizer.pdf

- Guided PracticeStudents will assist in putting ejection rubber close to the rule on the cutting die. Students will journal individually and then compare findings.

-

View/Download File: /project766_3815/Die_Cutting_Journal.pdf

- Independent Practice/Differentiated ActivitiesStudents will match samples to either cut, perforation, score, cut score or glue assist rule.

-

- Reflection on Employability SkillsA class discussion on what type of skills do you need for this career? (Measurement, critical thinking, planning, mechanically inclined and an understanding of paper characteristics)

- Lesson ClosureAn exit ticket that requires you to identify 2 out of the 5 types of rule on the table.

-

View/Download File: /project766_3815/Die_Cutting_Exit_Ticket.pdf

View/Download File: /project766_3815/Die_Cutting_Exit_Ticket.pdf

- Summative/end of lesson assessmentStudents will report out journal entry to class for discussion.

- References / Resources / Teacher PreparationAttachment: /project766_3815/cutting_die_and_rule.mp4

Attachment: /project766_3815/Die_Board_Graphic_Organizer.pdf

Attachment: /project766_3815/Die_Cutting_Journal.pdf

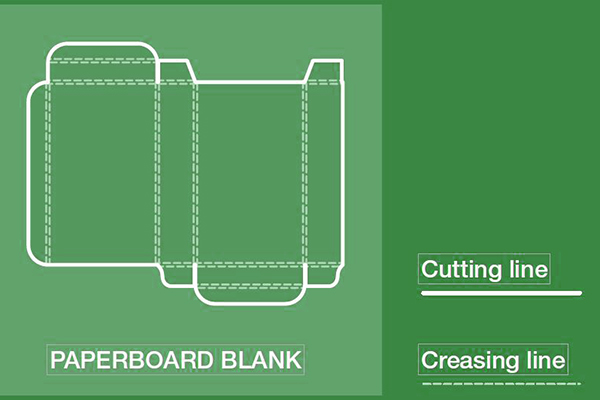

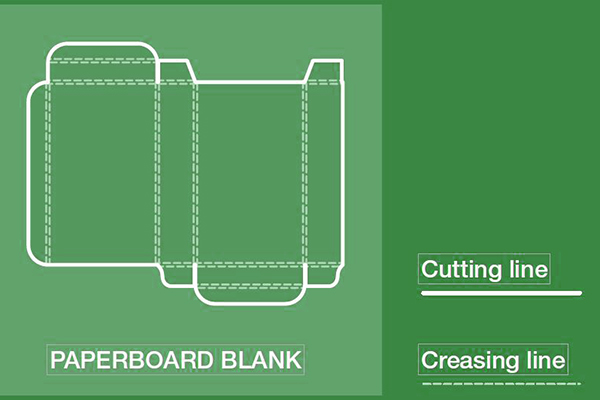

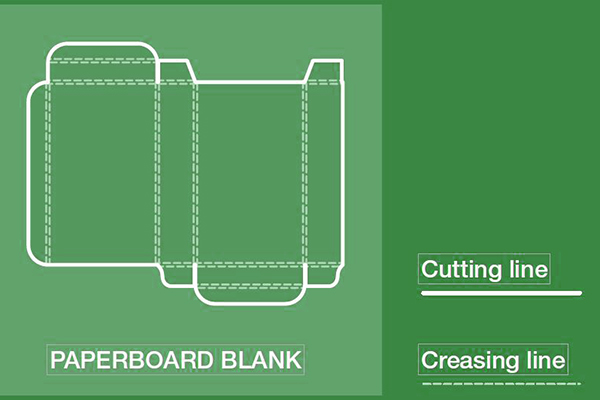

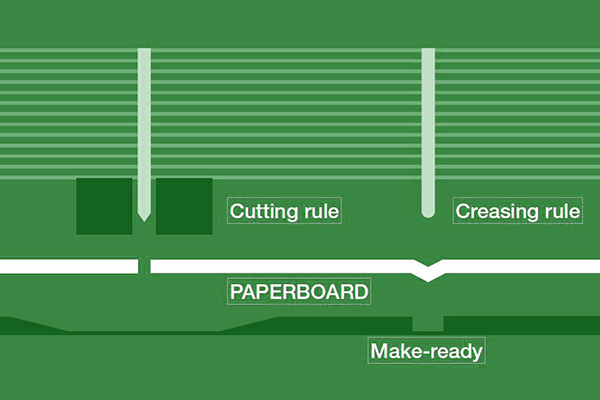

Attachment: /project766_3815/creasinglineandcuttingline.jpg

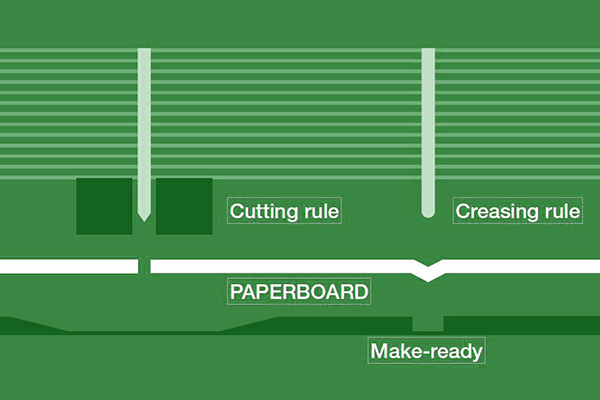

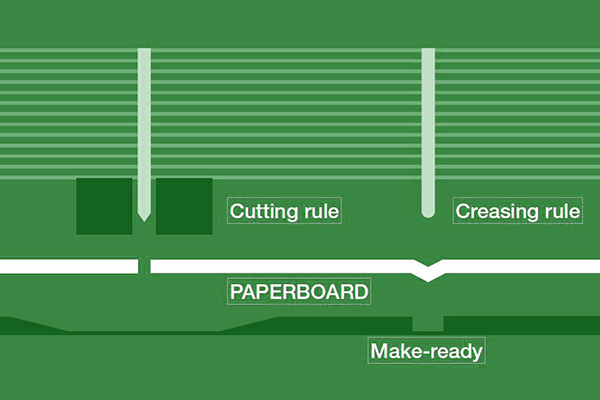

Attachment: /project766_3815/cuttingruleandcreasingrule.jpg

Attachment: /project766_3815/Die_Cutting_Exit_Ticket.pdf

Samples of various Rule

Cutting Die

Ejection Rubber

Elmers Glue

Lesson #3 | How to make a layout?

- Lesson Plan 3 TopicHow to make a layout?

- Lesson Plan 3 ObjectivesStudents will understand what is needed when nesting a layout.

- Anticipatory set or lesson opening (to activate students` prior learning or draw student interest or involvement)Student driven class discussion of the previous two lessons with the students sharing their strongest takeaways.Students will download the Cimpack die making demo software during instruction.

- Direct InstructionStudents will download the Cimpack die making demo software during instruction while watching the 6 minute video.

-

View/Download File: /project766_3815/Kasemake_layout.mp4

View/Download File: /project766_3815/18.0_CimPACK_Update_Synopsis.pdf

- Guided PracticeAfter handing out flat samples and large sheets of paper we will open the Cimpack software and find the type of structures that the students were handed. They will move them around the digital die board until they feel comfortable.

- Independent Practice/Differentiated ActivitiesStudents will trace the outline of their flat cartons onto the large sheet of paper, attempting to maximize the utility of the sheet and then try making the layout on the computer.

- Reflection on Employability SkillsClass discussion on the career path. It is high paying and in demand as the workforce for it is aging.

- Lesson ClosureThe exit ticket to write out what their two biggest takeaways are.

-

View/Download File: /project766_3815/Die_Cutting_Exit_Ticket.pdf

- Summative/end of lesson assessmentAssessment will be the drawn out layout sheet they created when trying to fit as many cartons on a sheet as possible.

- References / Resources / Teacher PreparationAttachment: /project766_3815/Kasemake_layout.mp4

Attachment: /project766_3815/18.0_CimPACK_Update_Synopsis.pdf

http://www.cimexcorp.com/downloads.htm

Flat sample cartons

24" 40" Sheets of paper

Lesson #4 | Die Cutting Press operation part 1

- Lesson Plan 4 TopicDie Cutting Press operation part 1

-

Web Link: Demo Bobst Novacut 106 E - YouTube

- Lesson Plan 4 ObjectivesStudents will understand the basics of platen die cutter press operation.

- Anticipatory set or lesson opening (to activate students` prior learning or draw student interest or involvement)Class discussion of previous days. Showing the cutting dies in house. Bringing up the memory of the day 1 video that showed an overview of die cutting and the press.

- Direct InstructionRun the feeder and delivery of the offset press showing that they are identical to the die cutting press.

- Guided PracticeThe class will watch the video and then assist me in setting up the manual die cutter.

-

View/Download File: /project766_3815/Manual_Die_Cutting_for_The_Melty_Misfits_stickers_boxes.mp4

View/Download File: /project766_3815/Die_Board_Graphic_Organizer.pdf

- Independent Practice/Differentiated ActivitiesStudents will take turns registering and operating the manual die cutter on their previously printed work.

- Reflection on Employability SkillsClass discussion on the high industry need for die cutter operators.

- Lesson ClosureExit ticket from each student comparing full size die cutting presses and manual die cutters.

-

View/Download File: /project766_3815/Die_Cutting_Exit_Ticket.pdf

- Summative/end of lesson assessmentAssessment will be the carton they die cut in class.

-

View/Download File: /project766_3815/Die_cutting_performance_rubric.pdf

- References / Resources / Teacher PreparationWeb Link: Demo Bobst Novacut 106 E - YouTube

Attachment: /project766_3815/Manual_Die_Cutting_for_The_Melty_Misfits_stickers_boxes.mp4

Attachment: /project766_3815/Die_Board_Graphic_Organizer.pdf

Attachment: /project766_3815/Die_Cutting_Exit_Ticket.pdf

Cutting Die

AccuCut Grand Mark 2 manual die cutter

Printed Samples to cut

Offset Press (AB Dick 9985)

Lesson #5 | Die Cutting Press operation part 2: Landing the plane.

- Lesson Plan 5 TopicDie Cutting Press operation part 2: Landing the plane.

- Lesson Plan 5 ObjectivesThis lesson ties together the previous 4 and strengthens understanding.

- Anticipatory set or lesson opening (to activate students` prior learning or draw student interest or involvement)Think, pair, share personal highlights from this unit. Students answers will be written on the board and provide talking points for the class discussion.

- Direct InstructionStudents will have a short discussion on blanking. How it is the final step in the die cutting process. It is essentially a second cut of the cut sheet. A knife outline that cuts through the nicks that held the sheet together.

-

Web Link: IML blanking cassette on BOBST EXPERTCUT 106 PE die-cutter - YouTube

- Guided PracticeStudents will have nicked and cut press sheets that they will break apart with pieces of rule. They will not how much waste is removed leaving only the final package.

- Independent Practice/Differentiated ActivitiesStudents will play the quizlet to review for the unit quiz.

-

Web Link: https://quizlet.com/_8ocmze?x=1qqt&i=qjkbm

- Reflection on Employability SkillsStudents will self reflect and think based on the knowledge they now have if die cutting is a career path that interests them.

- Lesson ClosureStudents will take and pass the unit quiz.

-

View/Download File: /project766_3815/Die_Cutting_Exit_Ticket.pdf

- Summative/end of lesson assessmentA unit quiz.

-

View/Download File: /project766_3815/Die_Cutting_Unit_Quiz__Google_Forms.pdf

- References / Resources / Teacher Preparationhttps://www.youtube.com/watch?v=BgVaRvRNwdw&ab_channel=BOBST

Nicked and cut press sheets

Web Link: https://quizlet.com/_8ocmze?x=1qqt&i=qjkbm

Attachment: /project766_3815/Die_Cutting_Exit_Ticket.pdf

Recommended Strategies / Instructional Techniques

Detailed Outline

- What is die cutting?Die-cutting is a manufacturing process in which a cutting die is used to cut folding carton structures in various substrates.

-

View/Download File: /project766_3815/basic_die_cutting.mp4

Web Link: Amazon.com: Martha Stewart Crafts Scoring Board and Envelope Tool

- What makes up a cutting die?A a cutting die is basically a giant cookie cutter in the shape of your structure. Folding cartons are produced using a custom steel die on a die cutting press. This fast paced manufacturing process speeds up production and ensures each product delivers a consistent result. Repeatability is critical!

Cutting dies are made with steel rule. Steel rule are strips of steel an inch wide. After being shaped they are pounded into the hard wood board. Different types of rule create scores, creases as well as cuts.

-

View/Download File: /project766_3815/cutting_die_and_rule.mp4

- How to create a Nest.Using Cimpack software the designer creates a layout. The layout involves the nesting of similar or different parts to be cut on a sheet maximize the material utilization. A good nest leaves little waste and will run through the die cutting press far easier.

-

View/Download File: /project766_3815/18.0_CimPACK_Update_Synopsis.pdf

View/Download File: /project766_3815/Kasemake_layout.mp4

- Die Cutting Press Operation Part 1Substrates are fed into the die cutting press the same way that it is fed into an offset printing press. Instead of putting ink onto the substrate, the paper is converted by cutting, creasing and scoring. These cut sheets are held together via nicks that carry it through the press.

-

Web Link: Demo Bobst Novacut 106 E - YouTube

- Die Cutting Press Operation Part 2In part two we expand upon what we‘ve learned, develop an understanding of blanking and review.

-

View/Download File: Blanking

Subject = CVTE | Grade Level = HS | Time Period = School Year | Program/Funding = | Externships-2020 |

Direct website link to this project: http://ContextualLearningPortal.org/contextual.asp?projectnumber=766.3815